There is no doubt that the invention of medical devices has revolutionized the healthcare industry and its innovations through research and technology implementation have continued to elevate the quality of life on a global scale. Medical device innovations help in including patients’ requirements correctly. They are also used to connect doctors with their users.

Today, various types of new technologies such as IoT i.e. The Internet of Things and 3D printing have transformed medical devices. You should note that innovation in medical devices does not just transform or update a particular aspect of the device but it also influences the complete life cycle of the medical device.

Medical devices have become more advanced than ever in the last 2 decades due to unprecedented research and advancement in medical technology. Medical technologies have merged and advanced to open new possibilities for healthcare professionals. These technologies have enabled healthcare professionals to diagnose and treat diseases much earlier, monitor health more closely, and take preemptive measures. In this article, we discuss medical device innovations and the technologies leading to them.

Innovations in Medical Devices are led by Medical Technology

What are Medical Devices?

Orthopedics utilizes various manufacturing processes such as machining, casting, grinding, polishing, metal injection molding, and rapid manufacturing to develop reconstructive devices, orthoses, arthroscopy instruments, knee replacement, and hip and spinal implants.

The evolution of medical devices begins from a problem to a solution i.e. functional in nature. It is further evolved for safety and comfort while ensuring that it has an ergonomic approach and can include technology that replaces mechanically operated functions. Manufacturers also ensure to enable the design such that it can integrate new materials in order to be aesthetically appealing.

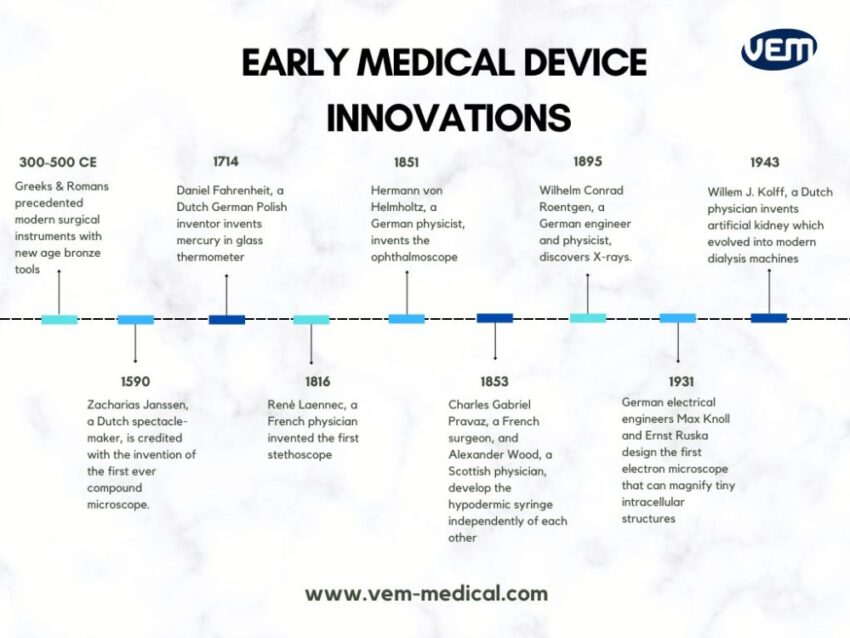

Earliest Medical Device Innovators

Before we get into modern medical device innovations, let’s take a look at some of the earliest medical device innovators. Their inventions have set a precedent for modern medical devices and their innovations.

René Theophile Hyacinthe Laennec (1781-1826)

René Laennec is referred to as the man behind the first stethoscope! He is a French physician who invented the design in 1816. The design was an ear trumpet pressed on the chest, and it was marked as an unprecedented innovation as for one of the first times, physicians could explore the inner workings of the body without performing surgery or cutting it open. This instrument enabled investigations of the heart and lung sounds.

Charles Gabriel Pravaz (1791-1853) and Alexander Wood (1817-1884)

The first hypodermic syringes were invented independently by Scottish physician Alexander Wood and French surgeon Charles Gabriel Pravaz in 1853. The basic injection principle was known through Greek and Roman physicians for at least 1800 years and they implemented the principle to use piston syringes that were thin and hollow to inject fluids into the body.

Hermann von Helmholtz (1821-1894)

Hermann von Helmholtz, a German physicist is considered to be one of the first biomedical engineers. He is known for the invention of the ophthalmoscope to examine the retina and other eye interiors.

Wilhelm Röntgen (1845-1923)

Wilhelm Röntgen, a German engineer and physicist is associated with the discovery of the X-ray and later, with the development of medical X-rays. The first X-ray images were published a month later by Yale professor Arthur Wright and the first clinical X-ray was taken at Dartmouth College in the same week.

How are Medical Devices used?

Today, medical devices are used not only by doctors or physicians but also by patients and paramedics. They are used in many diverse settings. For instance, they can be used in the following case scenarios:

- Patients can use them to self-monitor at home

- Opticians

- Dentists

- Paramedical staff and clinicians may use them in remote clinics

- Healthcare professionals in advanced medical facilities

- Medical professionals may use them for prevention and screening

Medical device technologies are used to diagnose, intervene and treat illness, monitor treatments, and assist disabled people. They enable common as well as complicated medical procedures such as bandaging a sprained ankle, diagnosing life-threatening diseases, implanting an artificial hip, or any surgical intervention.

Medical Devices consist of diagnostics imaging, IV Diagnostics, Consumables, Patient Aids, healthcare equipment and instruments, Dental instruments, Prosthetics, Patient monitors, oxygenators, ECG, etc.

According to WHO (World Health Organization), it’s estimated that there are approximately 2 million kinds of medical devices globally, in the healthcare market. They are categorized into more than 7000 generic device groups.

Medical Device Benefits

Innovations of medical devices are astutely explored by industry and healthcare experts to better healthcare services. Medical devices offer various advantages to healthcare service providers. In addition, its enhancements lead to better patient care quality! Let’s take a look at some of the benefits that medical devices offer:

- Medical devices are designed to deliver accurate results which assist clinicians in developing a more effective treatment plan.

- They can also deliver laboratory results and scans that are free of errors which helps to deliver improved results at a faster pace.

- Medical devices also provide better, more advanced, and less invasive treatment possibilities.

- They also help healthcare professionals by being accurate and efficient.

What is Medical technology?

Medical technology is a broader healthcare discipline that includes devices used in healthcare for the diagnosis, patient care, treatment, and health improvement.

Today, medical technology continues to develop rapidly. Medical technology has reinvented various medical devices by introducing exciting new trends in the areas of imaging and wearable technologies, 3D printing, and medical cables. Thus, medical technology advancement leads to the evolution and innovation of medical devices. Let’s further take a look at some novice medical technologies.

Novice Medical Technologies

Developing and gaining approval for a new medical device is often a slow and cautious process. The time frame completely depends upon the type of medical device being developed. The average time frame to develop a new medical device, all the way from concept to approval can take anywhere between 3 to 7 years and more. This time frame includes the entire device lifecycle such as research, development, and testing.

US FDA classifies medical devices based on the intended use of the device and also, upon the indications for use. You can understand these details further, in-depth on the US FDA website. Let’s understand the different classes of medical devices:

Wearable Health-monitoring Devices

Wearable health monitoring devices have made it easier than ever to track an individual’s habits, fitness levels, and overall health. In recent years, they have become increasingly popular as health tracking and monitoring devices.

They utilize a wide range of sensors that enable them to track a variety of health metrics such as heart rate, blood oxygen level, stress levels, skin temperature, and more. Some of the most common wearable health-tracking devices include fitness trackers, blood pressure monitors, sleep trackers, and smartwatches.

One of the biggest advantages of these devices is that they are extremely user-friendly and cost-effective. They don’t require users to schedule doctor’s appointments and can be simply worn on a regular basis to track and monitor various health metrics. These devices can also be customized to track specific health metrics for patients suffering from certain diseases.

DNA Sequencing & Genomics Research

DNA sequencing and genomics research have advanced our knowledge of genetic diseases and led to various medical discoveries. These discoveries have led to the innovations of various medical devices that can conduct genetic tests.

You should note that DNA sequencing technology has existed for a while, but it has recently taken a stride in becoming an affordable and efficient technology. Today, the cost of sequencing an entire genome has dropped significantly and can be completed in a short time frame.

With DNA sequencing, researchers can determine the genes of an organism and can predict the traits that the organism will pass on to its offspring. It can also be employed for determining the genetic cause of certain diseases and conditions. DNA sequencing can help researchers to track the genetic history of specific populations, identify variations in different populations, and predict the evolution of populations over time. DNA sequencing is also used to advance research in a variety of different fields such as identifying infectious diseases and viruses and developing treatments for them.

Robotics in Medicine

Robotics in medicine has gained increasing popularity in recent years. This technology has been used to automate and streamline various healthcare processes. This technology is mainly used in the operating room, but it is also used in other areas of healthcare such as rehabilitation and assisted living.

Robotic technology can improve accuracy by reducing human error. This is especially beneficial in operating rooms. This technology is also cost-effective and helps to improve efficiency.

Precision Medicine

As medical technology advances, more and more customization and personalization is being adopted by precision medicine. Precision medication has the capacity to revolutionize healthcare. This technology recognizes the individual genetics, environment, and lifestyle of each patient.

Today, precision medicine is most evolved in oncology and customizing cancer treatments. It works by attacking tumors based on the patient’s genetics, causing gene mutations and enabling the cancer drug to be more easily eliminated. It also has excellent potential in treating rare and genetic diseases, as well as infections!

Neurotechnology

Neurotechnology has the potential to improve various aspects of life. Neuro Devices are still in the research phase, but they have a lot of potential for treating brain disorders. One such example is Neuralink. This device will be embedded in a person’s brain. It would then record brain activity and potentially stimulate it.

As more and more research continues in medical technology and the field advances, it gives the potential for the healthcare industry to improve patient health by researching, developing, and incorporating these technologies through innovative medical devices.

Novice Medical Device Innovations and Trends

Medical devices aim to add convenience for the patient and the physician. Today, medical devices play a significant role in not only helping patients manage their medical conditions but also providing doctors and healthcare practitioners with the necessary information that they need to follow through with their patient’s progress.

Technology is ever-evolving and brings new, advanced developments in how patients and physicians can track medical conditions. Let’s take a look at some of the current medical device innovations and trends:

Tech Advancements in Diabetes

There are various medical devices that track and monitor diabetes. Diabetes is often referred to as a ‘slow-killer’ as it can cause many complications in patients. Many diabetic patients have to take daily blood sugar readings, to monitor their blood sugar levels. In more severe cases, the patient may need to perform blood sugar readings as often as 8-10 times per day.

Currently, a new medical device is under development that aims to regulate Type 1 diabetes by delivering insulin automatically. This device uses a novice concept of a closed-loop delivery system. FDA approved the first hybrid artificial pancreas version in 2016 and the latest device under testing is known as Control-IQ system. This technology will use algorithms to adjust a patient’s insulin doses automatically so that they no longer have to repeatedly test their blood sugar levels and remember to take their insulin injections.

Pacemakers Advancements

Pacemakers are life-saving medical devices but the batteries in the pacemakers need to be replaced every few years and that’s a major inconvenience as the patient has to undergo minor surgeries.

In the past decade they have undergone significant improvements. Today, they can record device data which can be monitored remotely via the doctors. There are even, newer models that are MRI-safe, and with a longer-lasting battery life that delays (but does not eliminate) the need for surgery to replace the battery.

Currently, there is a revolutionary technology being explored to develop a self-charging pacemaker. This technology will utilize the kinetic energy created by the heart and convert it into pacemaker power.

Heart Failure Detectors

Patients who are at high risk for heart failure are often implanted with a small medical device known as an ICD (Implantable cardioverter-defibrillator) or CRT-D (Cardiac Resynchronization Therapy Device).

A medical device called ‘HeartLogic’ is being developed and it can indicate/predict heart failure weeks in advance. This device is being developed by Boston Scientific and you can read more about it here. It’s a tiny device that is fitted with sensors and can track a patient’s vitals and heart rate, listen for changes in heart sounds, monitor respiration, and watch for shortness of breath. It can basically sense the body’s warning signs of potential heart failure.

Wearable Technologies

Wearable techs, such as FitBit, Apple Watch, and lung fluid vests are gaining popularity and may be undertaking significant advancements. This could be due to the fact that they aren’t invasive as compared to other forms of monitoring and diagnosis.

These devices enable patients to live comparatively, a normal life. A person that’s wearing a monitor that’s small or comfortable enough to wear day and night can provide data during real-world conditions. The information collected could give a doctor better insight into habits or lifestyle choices that contribute to their patient’s health.

Injection Molding in Medical Device Innovation & Manufacturing

Manufacturing medical devices is an extremely critical process as they need to be developed and manufactured with strict adherence to FDA regulations.

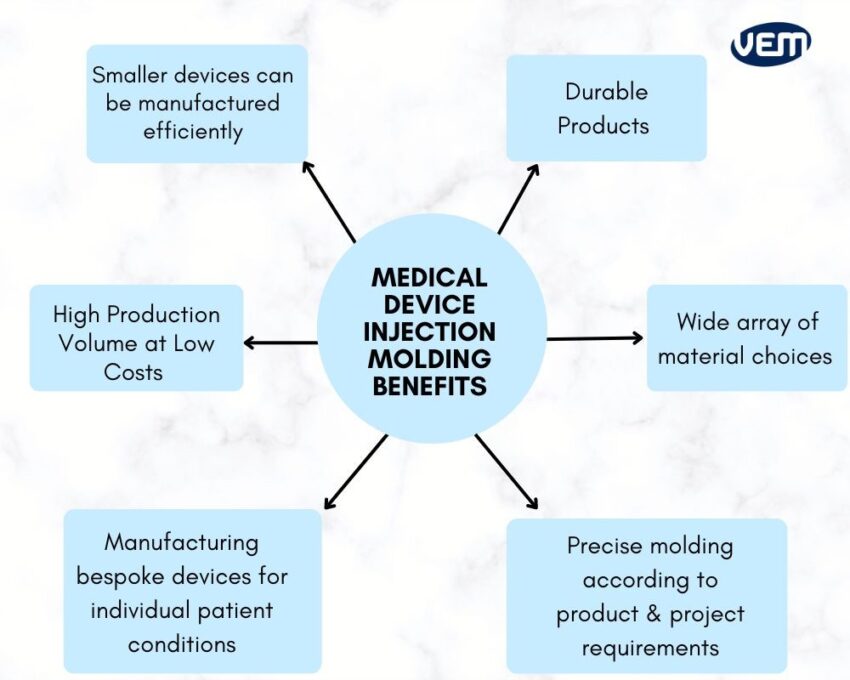

The medical device industry needs innovative device manufacturing techniques and reliable medical device manufacturers. Thus, medical device injection molding for manufacturing came to prominence as it supports the following:

- Medical devices that are even smaller than usual can be manufactured efficiently.

- High production volumes are supported at low costs.

- Precise molding according to product and project requirements.

- A wide array of material choices.

- Production of durable products.

- Manufacturing bespoke devices for individual patient conditions is possible.

Today, the market of injection-molded medical devices is expanding rapidly. It was worth $20.3 billion in 2021 and will continue to grow at 5.7% annually until 2030. You can read more about the medical injection molding market here. This growth is expected as there are various innovations happening at a rapid rate in the medical device industry. We have listed some medical device injection molding manufacturing techniques that are popularly used.

Liquid Silicone Injection Molding

Liquid silicone is a popular choice for medical device manufacturers because liquid silicone rubber (LSR) provides improved physical strength, chemical resistance, and thermal protection. Here are some of the ways to use liquid silicone injection molding in medical device manufacturing:

- Liquid silicone rubber demonstrates tight tolerances and its biocompatibility makes it an ideal material for creating surgical tools, drug-delivery mechanisms, valves, and masks.

- LSR is an excellent choice for consumer-grade products that regularly come in contact with the body. It’s a popular choice of material for manufacturing hearing-aid components and electric toothbrushes.

- Manufacturers routinely use LSR injection molding in healthcare-adjacent fields and products that include water heating and treatment components.

Metal-Based Injection Molding

Metal injection molding uses very finely ground metals mixed with binders to create feedstock which is then solidified and shaped to manufacture parts. After the part is manufactured, the solvents are removed from the binding agent leaving only the metal behind. MIM can be used to create many medical devices and components, which include but are not limited to the following:

- Medical and dental hand tools

- Implants and drug-delivery systems

- Robotic surgery implements

- Orthopedic assistance devices

You should note that devices and parts that require excellent maneuverability and mechanical strength are a good fit for MIM!

3D Printing

3D printing isn’t an injection molding technique in itself but can be used to complement medical device manufacturing. Currently, there are two ways to employ 3D printing for medical devices:

- A 3D printer can be used to print molds that are used for the medical injection molding process.

- It can also be used to create a proof-of-concept prototype.

You should note that 3D printing may not provide the tolerances required for some highly precise medical device products.

Gas-Assisted Injection Molding

Gas-assisted injection molding is employed when thicker-walled areas of the medical device mold cool as fast as the thinner ones during the injection. This mechanism enforces additional pressure so that the workpiece adheres tightly to the mold walls.

Gas-assisted injection molding solves this shortcoming and thus, unlocks a wider range of medical device designs. This technique makes it easier for engineers to create plastic parts with hollows and tubular sections without sacrificing the dimensional strength of the part. This technique enables the manufacturing of stronger and lighter medical implements and implants.

Medical Injection Molding Future

All medical devices and technologies must undergo years of testing and approval phases before they are approved for consumer use. As more and more medical devices and technologies clear the FDA’s process, AI is likely to play a greater role thus transforming healthcare in the near future.

The future of medical device innovation will take exceptional strides and we can be looking at high-tech, innovative medical devices in the upcoming decade. You can read more about medical device manufacturing here.

Let’s take a look at some of the approaches that the medical device manufacturing industry holds:

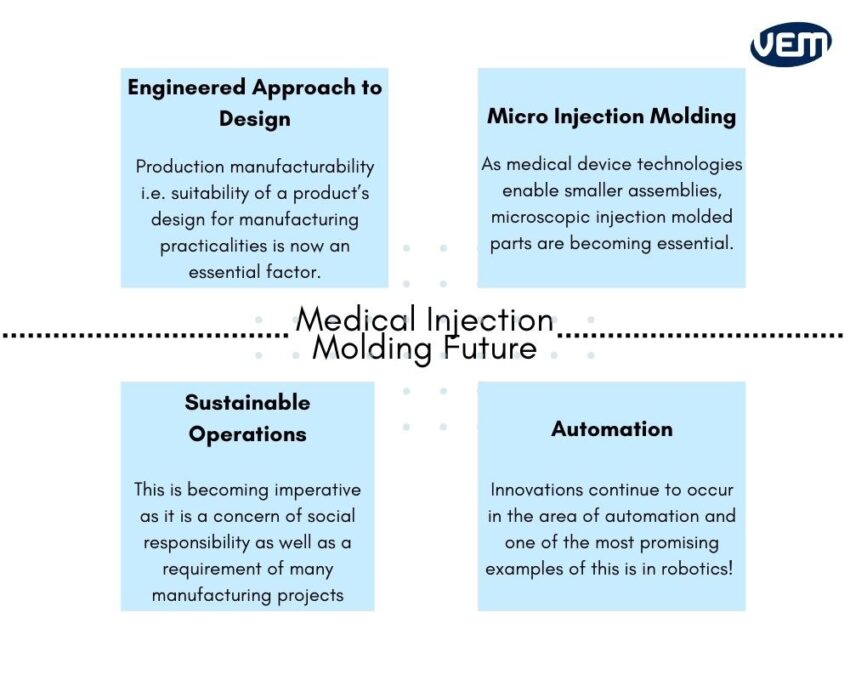

Engineered Approach to Design

A more engineered, and integrated approach to product design is taking hold in the industry. This essentially means that the production manufacturability i.e. the suitability of a product’s design for manufacturing practicalities is being considered much earlier in the process during design and prototyping. This enables a smoother, faster overall design and production cycle.

By including best practices such as rounded corners, support ribs, and other aspects of injection molding much earlier, the gap between the initial design and the final product is becoming narrower.

Micro Injection Molding

Micro molding is the practice of injection molding parts at a microscopic scale, sometimes at dimensions down to the micron level. As medical device technologies enable smaller assemblies that can perform life-saving procedures, less invasively, these microscopic injection molded parts are becoming essential.

A suitable micro molding vendor, however, must not only be able to mold parts at a tiny scale but must be able to measure and analyze tolerances, part errors, and defects. At such a small scale, there is no room for any margin for error.

Sustainable Operations

Sustainable operations are both a concern of social responsibility as well as a requirement of many manufacturing projects. The future of medical device manufacturing is focused on creating efficient production equipment. This means that an injection molding machine can go through the same number of cycles even after five years, from the date of the purchase.

Automation

Innovations continue to occur in the area of automation also and one of the most promising examples of this is in robotics, where ‘smart’ robots are advanced enough to work side by side with humans. This aids the typical automated areas of a production facility, which are sometimes not suitable for people to work within.

AI and Cloud Technologies

AI and Cloud technologies are not completely established but they are one of the most actively researched domains. The intent of AI and Cloud technologies in medical devices is to gather, centralize, and store the data. The ability of the hardware of the medical devices to shrink down through cloud computing will enable it to make the medical devices even smaller.

Cloud computing has already shown a significant upgrade through EHR (Electronic Health Records) in the healthcare industry. What was once a slow and tedious process of obtaining patient records has now turned into an extremely efficient process! A similar vision is being explored for medical devices.

Bring your medical device innovation to life

We believe in offering the most updated information and the best-suited technique and services to our customers!

At VEM Tooling, we are very process-driven and effective at manufacturing high-quality medical devices. Our team has immense experience in setting up a robust manufacturing process for medical device manufacturing via injection molding. If you are searching for a medical device manufacturer, you can contact us to solve any query.